Hot-selling Oxidised Polyethylene Wax For Stabilizer - High viscosity cracking Polyethylene wax SX-70 – HAIXING

Hot-selling Oxidised Polyethylene Wax For Stabilizer - High viscosity cracking Polyethylene wax SX-70 – HAIXING Detail:

Product Properties:

| Melting point ℃ | 110±3℃ |

| Viscosity cps@140 ℃ | 3000-5000 |

| Penetration | 4-6 |

| Density G/cm3@25 ℃ | 0.92-0.94 |

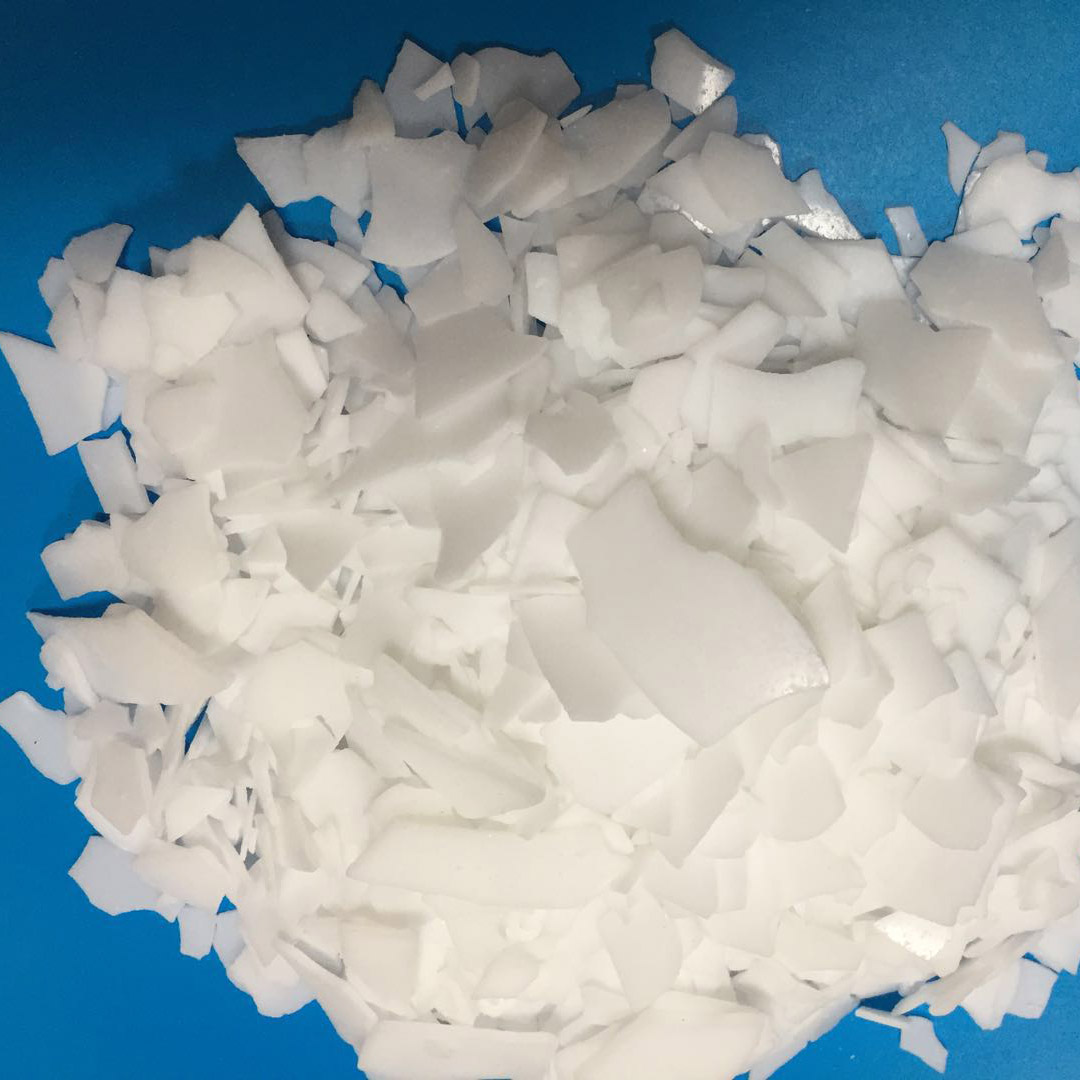

| Appearance | White powder /bead/granule |

Using advantage

Our pe wax is produced by pyrolysis (cracking )method . It has good wetting for all kinds of pigment as the pigment`s dispersion . And has the function of decreasing the system`s viscosity and increasing flowability and improve the masterbach`s production efficiency ,raise the output of production .and allow to higher pigment`s concentration .

Better thermal stability

Higher pigment loading capacity of up to 75% inorganic pigments .After the pigment is added to the polymer, its processing fluidity will be reduced to varying degrees. PE wax is added as a lubricant dispersant, which can promote the highly dispersed pigment on the one hand and give the material high flow performance on the other hand. Therefore, the appropriate ratio of pigment and PE wax is the key to master color production and quality assurance. In the preparation of color masterbatch, add polyethylene wax as dispersant, on the one hand, wet pigment particles, improve the interface state of pigment and resin, make pigment easy to disperse; On the other hand, the entanglement of polymer molecular chain is reduced, which lubricates the polymer molecular chain and accelerates the movement of polymer molecules, thus improving the processing flow performance of the blend.

Wider compatibility ,not only for polyolefin but also for engineering plastics .

Can reduce the degradation of pigment

1)Act as the lubricant, cost-saving agent and release agent in the course of extruding, calendering, injecting, blowing molding of PE, PP and other plastic.

2) Act as the dispersant for masterbatches, pigment, carbon black, additive for parent material, filling parent material and other pigments.

3) Applied in the field of hot melt road marking material.

4) Act as the additive for shoeshine, floor wax, car wax, polishing wax, chinaware, pill wax, paint, coating, cable, carbon paper, wax paper, textile softening agent etc.

5) The additive for rubber process and car anti-rust agent etc.

Product applications:

Common color masterbatch

Black masterbatch

PVC processing

Road marking

Rubber processing

Cable

Watterproff roll material

Package and storage

Polyethylene wax is packed in woven bags with internal plastic bags with 25KG each net weight. It must not be drenched by rain and scorched by sun. It can be stored for two years.

Product detail pictures:

Related Product Guide:

We enjoy an extremely good status among our prospects for our great merchandise top quality, competitive price and the ideal service for Hot-selling Oxidised Polyethylene Wax For Stabilizer - High viscosity cracking Polyethylene wax SX-70 – HAIXING , The product will supply to all over the world, such as: Curacao, Zambia, Greece, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.