Cracking POLYEHTYLENE WAX : SX-115

| Specification | SX-115 | Te sting standard |

| Melting point ℃ | 115±5 | ASTM D87 |

| Viscosity | 300-400 | ASTM D445 |

| Density(g/cm3@25℃ | 0.93 | ASTM D1505 |

| Penetration(dmm@25℃) | 2﹣4 | ASTM D1321 |

| Molecular weight | 4500 | ………… |

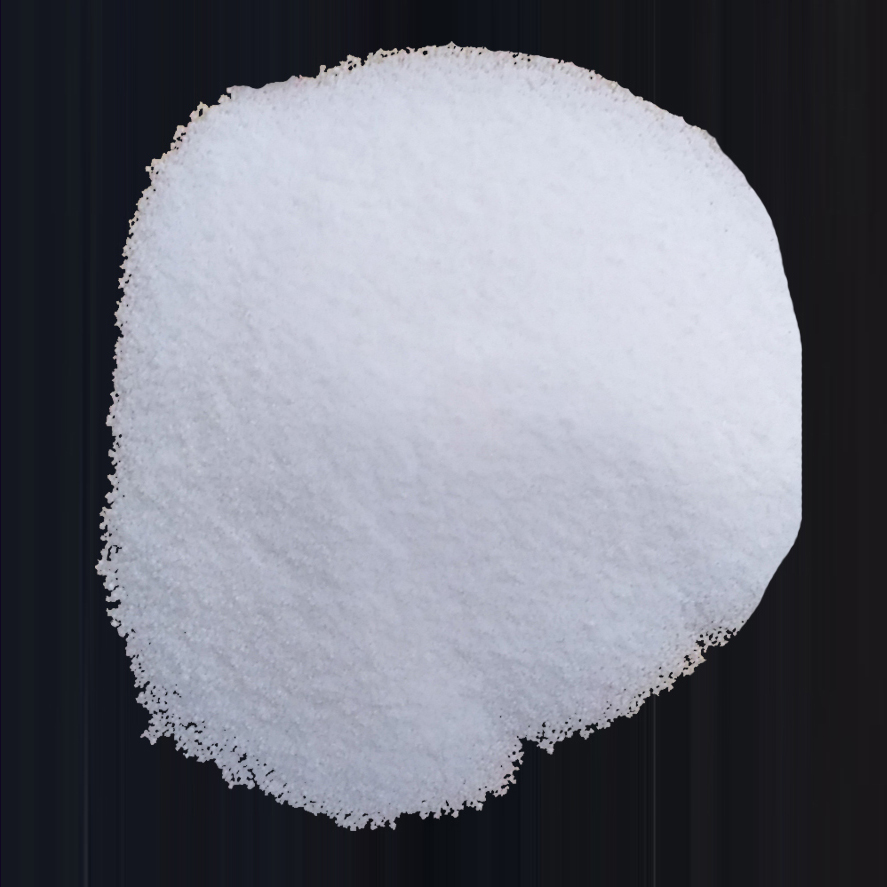

| Appearance | powder |

Lubricating –Act as the lubricant, cost-saving agent and release agent in the course of extruding, calendering, injecting, blowing molding of PE, PP and other plastic. offering both internal and external lubrication due to decreased friction

Wetting and dispersing –Act as the dispersant for masterbatches, pigment, carbon black, additive for parent material, filling parent material and other pigments. low viscosity enables pe wax to wet pigments or additives easily, resulting in higher dispersion quality

Surface modifying –Applied in the field of hot melt and road marking material. for improved hydrophobing, sealing, smoothness, gloss, matting, slip, anti-blocking, scratch resistance, abrasion resistance and mar resistance in coatings and printing inks

Retention / rheology – to produce pastes for polishes or adjust rheological properties in coating formulations

Release / parting – inert, non-sticky films formed and used as mould release agents

Viscosity adjustment – reduction of viscosity to assist final product processing.

Act as the additive for shoeshine, floor wax, car wax, polishing wax, chinaware, pill wax, paint, coating, cable, carbon paper, wax paper, textile softening agent car anti-rust agent etc.

APPLICATION:

1.PVC profile ,pipe ,foaming board,wood plastic.

2.Color Masterbatch,filled masterbatch,modified masterbatch ,functional masterbatch.

3.PVC stabilizer

4.Hot melt adhesive

5.Paint ,paint,road marking paint

6.Paraffin wax,

7.Rubber processing