Factory wholesale Oxidized Hdpe Pe Wax - HIGH DENSITY OXIDIZED POLYETHYLENE WAX :SX-36 – HAIXING

Factory wholesale Oxidized Hdpe Pe Wax - HIGH DENSITY OXIDIZED POLYETHYLENE WAX :SX-36 – HAIXING Detail:

| Specification | SX-36 | Testing standard |

| Softening point ℃ | 140±5 | ASTMN 1319 |

| Density(g/cm3@25℃ | 0.98-1 | ASTMD1505 |

| Penetration(dmm@25℃) | ≤1 | ASTMD1321 |

| Molecular weight | 8500-12000 | ASTMD445 |

| Acide value(mgKOH/g) | 16±2 | ASTMD1386 |

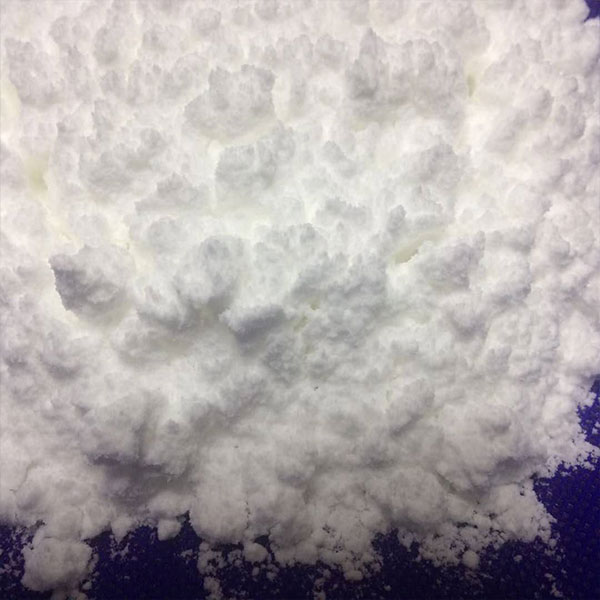

| Appearance | powder | ……………… |

PVC transparent products/ransparent film lubricants

SX-36 high-density oxidized polyetylene wax such as SX-36 shows outstanding performance for transparenet product application ,especially for PVC film produced by blowing and extrusion process .It has been proven to be an unique solution .

Since transparent products have a high requirement for lubricants and also transparency ,and general external lubricnts will make PVC opaque,whereas SX-36 does not affect the transparency of transparent products while also helping melt flow and metal release.It has been recognized as the most effectiv product in the market .

PVC foam board lubricants

SX-36 high-performance lubrican products have been proven to provide effective performance .it can also customize the formulations according to the product requirement to meet diversified demands of lubricants from customers .

It has excellent metal release effect , fusion promote effect , dispersion effect for filler ,reduces plate out/longer working hours , provides a wilder processing window,especially for some special foam products .

PVC edge band lubrciants

For PVC edge band application , it is essential to ensure smooth processing and no immigrated wax to surface and influencing downstream processing ,Such as printing/lamination etc. SX-115 and SX-36 can help PVC edge band enterprises to improve product quality and reduce scrap rate .

It can effectively promotes melt fusion , promotes fusion speed ,improves metal release and reduces plate out effectively .

Applications

PVC foam board

PVC advertising board

PVC cabinet board

PVC transparent tile

PVC floor, PVC SPC floor

Building template

Advantages

Plasticizing: increasing plasticizing while reducing torque;

Demoulding: It can reduce the adhesive force of thermoplastic melting and increase the melt fluidity, improve demoulding and increase the output;

Lubrication: improve gloss and appearance of finished products;

Product detail pictures:

Related Product Guide:

We constantly function like a tangible group to ensure that we can give you the very best high-quality and also the very best cost for Factory wholesale Oxidized Hdpe Pe Wax - HIGH DENSITY OXIDIZED POLYETHYLENE WAX :SX-36 – HAIXING , The product will supply to all over the world, such as: Algeria, Rio de Janeiro, Albania, We are introduced as a one of the growing manufacture supplier and export of our products. We have a team of dedicated trained professional who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.